Hilti HDK spits before and after setting.

Wookey

As part of this year's techno-overkill we succeeded in getting ourselves sponsored by the nice men at Bosch to the tune of one cordless hammer drill. This, actually a GBH 24VRE, soon became named Geraldine B. Heronworthy, and was affectionately known as just Geraldine.

First a bit of spec: the drill has an SDS chuck which allows easy changing of bits by hand with no chuck key to lose underground. It comes with a 1.2 amp hour battery which fits into the handle.

The first thing we did was adapt the drill for underground SRT use. We added a chain handle with which to hang it from a harness. Tony produced a wooden insert to plug in instead of the normal battery which had a curly cable attached so that an external battery could be used. Animal's Photon Cannon battery was ideal for this as it was 24V and designed to be caveproof so a connector for this was fitted. On testing in Settle carpark one weekend the drill seemed to go slower than with its own battery but this didn't seem likely to be much of a problem. Also a protective baggy was constructed by Julian to allow Geraldine to survive the caving experience.

In order to test the drill to determine both it and the battery's performance we procured a kerbstone from some roadworks and proceeded to drill holes in it. This also ensured that the battery had been given its first few discharge cycles to get it up to full capacity in accordance with Bosch's instructions. True to form the number of holes (30mm deep with the 13mm bit provided) went from 14 to 19 over five charge-discharge cycles. We also compared the drill with a standard mains powered Black and Decker drill with hammer action and it proved to be able to drill holes about five times as fast (taking between 20 and 45 seconds depending on how hard the user pushed).

One problem with using a power drill for SRT bolt holes is that the holes drilled have conical ends and so it is very dodgy putting the standard self-drilling anchors in as their strength depends on the wedge (cone) being driven in by the end of the hole. If this end is not flat the wedge may move further into the hole rather than properly expanding the spit. It is also difficult to drill the holes to exactly the right depth with the drill, where only about 1.5mm of error either way can be accepted. Both these problems can be dealt with by finishing off each hole with the standard self-drilling technique but this means that a complete normal bolting kit must be carried along with the Drill bolting kit, which means yet more gear and is not a very pleasing solution.

A better solution is to use different anchors, specifically designed for use in conical holes. Discussions with Messrs Cordingley and Carter one night in Green Close about their aven bolting activities produced a recommended anchor - the Hilti HDK. These are also quite happy in holes which are too deep as they don't use the end of the hole at all.

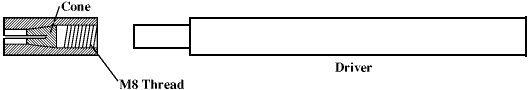

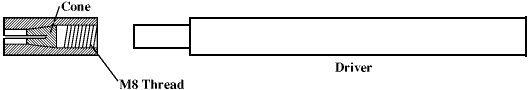

We found the Cambridge Hilti distributor and boogied on down with grubby surveys clutched in our sweaty paws with intent to scrounge/buy some anchors. The Hilti man was astounded to discover that we were using spits around their maximum stated loads, carefully ignoring the usual safety margin! Having decided that we were nutters he was very helpful, demonstrating the HDK spits with their internal wedges which are driven out with a special driver, and photocopying the spec (see later). We even got a 15% discount out of him. We would have liked to buy stainless anchors in the interests of longevity, and thus indirectly safety and conservation, but at 28 quid for a box (100) of galvanised and 109 quid for a box of stainless we decided that we couldn't afford to be altruistic.

Tony provided a block of limestone which had been destined for someone's rock garden to further our experiments as all the Hilti figures were for concrete, as were our kerbstone holes. We had expected to get many fewer holes per charge but only actually got about 10 to 15% fewer. We now changed to using a 10mm bit to correspond with the new HDK spits. These spits have the same 8mm thread as the old spits (so all our hangers would fit) but can have thinner walls as they don't have to be strong enough to be hammered whilst drilling.

With this smaller bit we got significantly more holes per charge although there was significant variation in how many we actually got (between 34 and 22). We assume that this variation was caused by different duty cycles, temperature and technique. We tried drilling holes with heavy pressure as fast as possible which resulted in both drill and battery becoming very hot, and drilling with lighter pressure and a 5 second gap between holes which gave a cooler drill and more holes.

We also tried placing a couple of bolts and found that when setting them the driver wouldn't quite go all the way in, as it had when demonstrated in the shop (in air), and when used on KK. We wondered about this but didn't realise that it was to become more significant in Austria.

A limited rock surface, the time consuming nature of the tests, and the complaints about noise and vibration from three floors up (the rock was living on Del's Churchill windowsill) all conspired to limit the total amount of testing, making our conclusions somewhat tentative.

It seemed from our experiments that the supplied battery had sufficient capacity to be useful so only one spare would be required for recharging back down at base. Also some practise in drilling the holes and placing the spits before trying it underground is beneficial.

So out in Austria Geraldine and a couple of BDH's, each containing bit, driver and some spits, were transported up to the cave, along with all the rest of the rubbish. Her first job was re-rigging Checkout (the third pitch) yet again, and putting in bolts for the Dreamtime traverse (wielded by Dave). The next day she was taken down to attempt the Yapate climb, and used to re-rig Bungalow Pitch on the way (Jeremy taking three attempts to get a bolt set properly as he hadn't practised it before).

Unfortunately the battery went flat after just half a hole at Yapate. This meant that despite the 30-odd holes on the surface, we were only getting nine holes underground - bloody typical. This sort of performance continued throughout the Expo, although the total use was not that high for reasons which will become clear shortly. Unfortunately there was never an opportunity to just use a whole battery in one go so the discharge always took place with at least one night's sitting around between start and finish. We came to the conclusion that a combination of the low temperature reducing the battery's dischargeable capacity, and a high self-discharge rate whilst not in use gave us this reduction in effective capacity.

After the flat battery episode Geraldine sat around for a bit until a tourist trip near the entrance started down Checkout. Mark Scott was the unfortunate who tried to abseil from one of the rebelays rigged with the new spits when it fell out. This, not surprisingly, led to some distrust of our amazing new technology so Geraldine lay disused for a time until Wookey and Dave brought her back up to the surface.

The fact that it seemed to be impossible to set the spits according to the instructions, (ie. getting the driver shoulder flush to the head of the spit) was primary suspect for the spit not holding properly. The problem with this was that if Dave couldn't set them then no-one else stood much chance. The testing took the form of putting bolts into boulders, tying them to something and throwing them off a nearby cliff. The first bolt split its rock so we tried a bigger one (estimated at 40 kilograms). A ring hanger was used as it could be loaded outwards, and about 2 metres of 10mm Edelrid attached that to a sling hooked over a suitable projection.

A fall factor one test went off fine so we tried a couple of Fall Factor 2s and still failed to even damage anything. We then tried throwing the rock downwards to get a fall factor higher than two but on the second attempt at this the sling bounced off and the rock bounced down the mountain. It was retrieved but snapped in half across the bolthole as it was being dragged back uphill. The set spit could thus be examined and it could be seen that it really didn't expand very much at all inside the rock.

Next we searched for a really big rock which was sufficiently close to the edge that we could slide it off. The one chosen was estimated to weigh 150 kilograms. This did the trick and snapped the tape with what was probably slightly less than a fall factor one fall. The rock shattered in the fall so we were able to retrieve the remaining 30 kilogram bit with the hanger in it to put on display as testimony to the strength of Hilti spits. The rope sheath had melted just above the Figure of Eight through the ring hanger, and it was probably this which had caused the burning smell we had noticed as the rock fell. We assume that the rope must have been slightly nicked or damaged at this point as one would expect it to melt or snap at the knot in this sort of test.

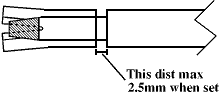

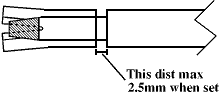

This testing convinced us that the new spit and drill combination was fine as long as the driver shoulder goes to within at least 2.5mm of the spit. However, it shed little light on the reason for the bolt failure. We can only assume that it was not set well enough, and users should make an effort to belt them as hard as possible to ensure reasonable setting. This attitude can be taken too far, as was demonstrated by Del and Dave on the very last day's pushing when they sheared one of the drivers off whilst attempting to ensure that the spit was properly set.

Geraldine was next used down at the bottom of Endless to rig the Hasta La Vesta/Captive Wedge/Half Shaft series over a couple of trips. This allowed a couple of silly rebelays to be rigged which would have been practically impossible to do by hand. It also demonstrated just how fast rigging can be done with the aid of a drill.

Overall the drill was used much less than it could have been due to lack of confidence, lack of experience, and poor battery logistics. Despite the fact that we had two batteries no-one could be bothered carrying Animal's big one underground as it promised no more power than the standard battery. Inefficiency also resulted from the battery's habit of discharging itself if left waiting in the cave. Hopefully these problems can be resolved next year to make better use of Geraldine. A new battery will be constructed and some more thorough tests done to discover how we can get the best out of it. A new baggy will also be made as the original is damaged, and needs a bit of redesign anyway. Also, anyone who expects to use the drill next year should have a practice above ground first. And finally, discussion with Hilti will hopefully produce some solution to the problem of insufficient expansion in limestone.